Sheathed thermocouples by WIKA?

Sheathed thermocouples differ from conventional thermocouples in their smaller construction and their flexibility. Due to this feature, sheathed thermocouples can also be used in places that are difficult to access.

In our extensive range of sheathed thermocouples, you can find a suitable version for every application.

What is a sheathed thermocouple?

Thermocouples consist of two metal conductors of different materials which are welded together at the measuring point. In a sheathed thermocouple, the thermocouple is embedded in a highly compressed ceramic powder. Depending on the alloy of the sheathed cable, sheathed thermocouples can be used for temperatures above 1,000 °C. In addition to their mechanical and thermal robustness, sheathed thermocouples have the great advantage that they can be constructed to be very thin and also flexible. This makes it possible to reach measuring locations that are difficult to access. In addition, no moisture can penetrate and interfere with the measurement because the sheathed thermocouples are tightly welded to be sealed. Sheathed thermocouples are very robust and particularly suitable for high temperatures.

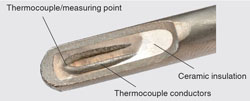

How is a sheathed thermocouple constructed?

Sheathed thermocouples consist of an outer metal sheath, which contains the insulated internal leads, embedded within a high-density ceramic compound (mineral-insulated cable, also called MI cable). Sheathed thermocouples are bendable and may be bent to a minimum radius of five times the sheath diameter. The extreme vibration resistance also supports the use of sheathed thermocouples.

Design of sheathed thermocouples

Sheathed thermocouples consist of an outer metal sheath, which contains the insulated internal leads, embedded within a high-density ceramic compound (mineral-insulated cable, also called MI cable). Sheathed thermocouples are bendable and may be bent to a minimum radius of five times the sheath diameter. The extreme vibration resistance also supports the use of sheathed thermocouples.

For sheath materials, Alloy 600 or stainless steel are used preferentially. Alloy 600 (2.4816 Ni alloy) is the standard material for applications which require specific corrosion-resistant properties under exposure to high temperatures, resistant to induced stress corrosion cracking and pitting in media containing chloride. Sheathed thermocouples from Alloy 600 are resistant against halogens, chlorine, hydrogen chloride and ammonia in aqueous solutions. Sheathed thermocouples from 316 stainless steel feature good resistance against aggressive media and also against vapour and combustion gases in chemical media.

Which sheathed thermocouples are used most frequently?

Type K: NiCr-NiAl thermocouples are suitable for use in oxidising or inert gas atmospheres up to 1,200 °C (ASTM E230: 1260 °C) with the largest wire size.

Type J: Fe-CuNi thermocouples are suitable for use in vacuum, in oxidising and reducing atmospheres or inert gas atmospheres. They are used for temperature measurements up to 750 °C (ASTM E230: 760 °C) with the largest wire size.

Type N: NiCrSi-NiSi thermocouples are suitable for use in oxidising atmospheres, in inert gas atmospheres or dry reduction atmospheres up to 1,200 °C (ASTM E230: 1260 °C). They must be protected from sulphurous atmospheres. They are very accurate at high temperatures. The source voltage (EMF) and the temperature range are almost the same as with type K. They are used in applications where a longer service life and greater stability are required.

Type E: NiCr-CuNi thermocouples are suitable for use in oxidising or inert gas atmospheres up to 900 °C (ASTM E230: 870 °C) with the largest wire size.

Type T: Cu-CuNi thermocouples are suitable for temperatures below 0 °C with an upper temperature limit of 350 °C (ASTM E230: 370 °C) and can be used in oxidising, reducing or inert gas atmospheres. They do not corrode in moist atmospheres.

The information on the use of sheathed thermocouples refers to versions with direct contact to the medium.

We recommend that you clarify the temperature range, accuracy classes and dimensions of these "noble" PtRh-Pt (platinum/rhodium-platinum) mineral-insulated thermocouples with your responsible contact person.

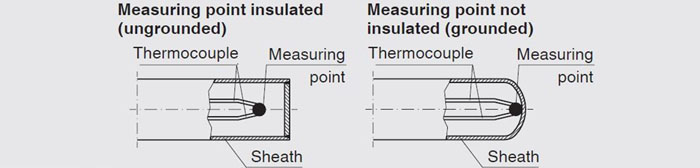

What is the difference between an insulated and a non-insulated measuring point?

One differentiates between insulated and non-insulated measuring points. In the case of insulated measuring points, the measuring point is not connected to the outer sheath (ungrounded measuring points), while in the case of non-insulated measuring points it is welded to the outer sheath (grounded measuring points). Insulated measuring points make the sensor somewhat more slow-acting thermally, but also less sensitive to interference during signal transmission. Sheathed thermocouples with grounded measuring points have a very fast response time, but are much more sensitive in terms of signal transmission.

Sensor tip designs of sheathed thermocouples

Contact us

Would you like further information? Write to us: