-

Home

-

Products

Tubeskin Temperature Measurement Solutions

Request infoWould you like further information? Write to us.

To the form

Tubeskin thermocouple application overview

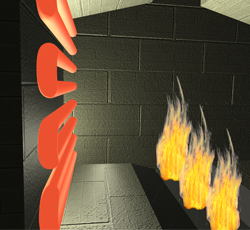

Radiant Furnace Section

The radiant section is typically where the radiation from the flame heats the tubes. The tubes can be vertical or horizontal, arranged along the refractory wall, in the middle or arranged in cells. The tubes are typically 300-450 mm (12-18”) apart inside the furnace. In the example on the right, the tubes are horizontal and burners are in the middle of the furnace.

Convection Furnace Section

The convection section is located above the radiant section. In this area, the heat is not as intense and the tubes are typically not subjected to direct flame. Here, the tubes are typically 150-230 mm (6-9”) apart inside the furnace which sometimes makes it difficult to attach tubeskin thermocouple sensors. Typically, tubeskin thermocouple sensors are only installed on the bottom row (shock tubes).

Purpose of Tubeskin Measurement

The purpose of tubeskin thermocouple measurement is to determine tube life, trending, and provide safe guards within a system. By relying on accurate tubeskin thermocouple sensors, clients can safeguard heater operations at their facilities. This can increase tube life in furnaces and increase production.

In order to successfully achieve the purpose of tubeskin measurement, thermocouple systems should meet all of the following requirements:

Accuracy - Provide accurate data to determine tube life assessment.

Durability - Withstand harsh firebox environment for prolonged periods and should last the minimum of one turnaround cycle.

Ease of installation - Secure weld attachment to the tube wall to fit any size pipe; Fast installation to meet tight maintenance schedule during a shutdown; Quick replacement during shutdown.

Sensitivity - Able to detect overheating early on from coke formations; Allow for adjustment of furnace firing.

Safety device - To monitor temperatures and alert in cases where high temperature is reducing remnant life or exceeding maximum allowable limits.

Design considerations

WIKA/Gayesco uses trained specialists to custom design the thermocouple system to the application. These specialists utilize best practices derived from scientific properties to optimize the life and accuracy of the thermocouple. These specialists even look to how the process unit is going to be used to optimize the system for temperature, movement, and burner firing.

Today, many major refiners, process licensors, and furnace manufacturers rely on WIKA/Gayesco Services to provide tubeskin thermocouple systems for them. Can we design a system for you?

Contact us

Would you like further information? Write to us:

Services brochureA brochure detailing all of WIKA Canada's field service options for clients.

Gayesco